Our Used Textile Machinery

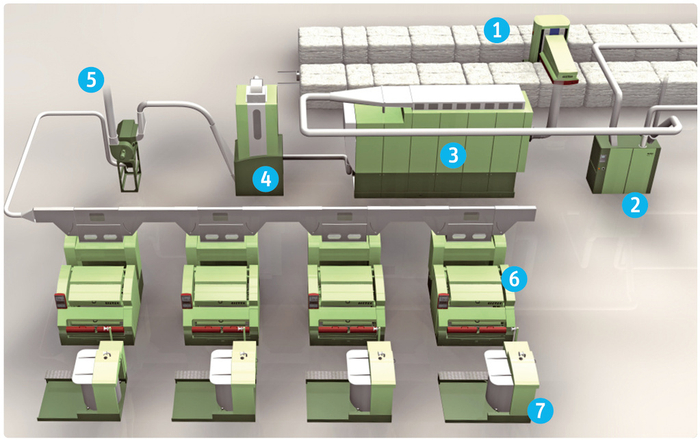

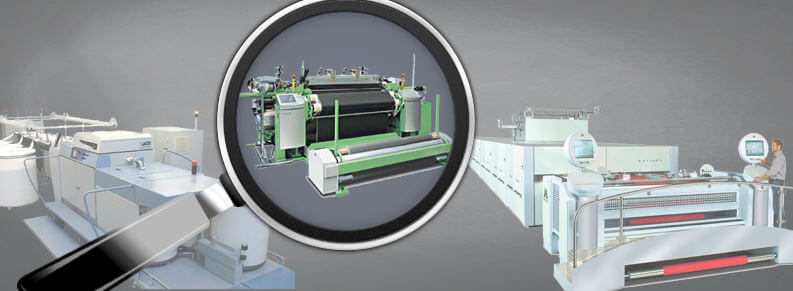

Please find the complete and current list of our second-hand textile machines for wool / acrylic spinning, cotton spinning, weaving, non-woven, dyeing, finishing, knitting and any other used textile machines available subject to prior sale. You will also find several lots of machines for sale and complete units and production lines for the textile area. Our used textile machines catalog is updated regularly and all our textile equippements for sale are owned by COGLIANDRO or under our exclusive control !