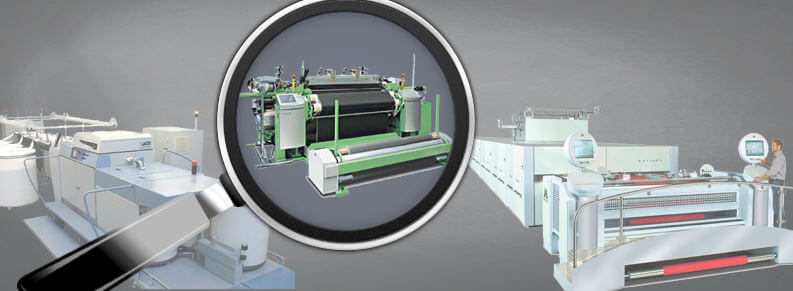

Complete spraybonding and thermobonding wadding line for sale

Year: assembled end of 1989, Production started : 1990

Final wadding width 3.20 m, production range 45 g/m2 to 1500 g/m2 .

This line works with polyester, wool and cotton fibers or mixed ones.

-three bale opener ; with a fiber mixing station and air transport feeding system to the card.

- three conveyor

belts and complete electric panels.

- 3.50 m double doffer carding machine Bonino made,

-Cross lapper width 5 .0 m, Automatex made,

- soft stitch quilting machine width 2,40 m ( Mecca ),

- Three compartments high capacity oven German manufacturer ( MOHR ) with

2 Spray cabine press also inside the Oven

- cutting and winding machine (AUTOMATEX),

- waste recycling machine (MASIA),

- automatic packaging machine ,big gas tank, resin resin mixing station. Compactor (Magenta)

This wadding Line is capable to process fibres of polyester,

wool, polypropylene, cotton.

Fibre data are DTX 2.50 up to DTX 30, and cut 38 mm up to 90 mm.

Best cut is 60/64 mm. The 90 mm is for wool. By changing the card wires you

can alter fibre specs.

Our line can produce wadding 45 g/m2 up to 1300 g/m2 ( compressed for

needle punching.Every day production g/m2 45 to 800.

Regarding the product thickness keep in mind that all wadding lines produce

calculating the wadding weight and NOT the thickness. Thickness can be altered

by reducing the wadding volume either inside the oven press or on hot calender

for fine tuning.

Our products support the following market sectors:

Furniture upholstery

Clothe manufacturing ( sports-ski jackets- leather coats etc )

Quilting ( Quilts, bed covers, pillows, baby sleeping articles, sleeping bags,electric blankets)

Mattress making ( inside the mattress, quilted mattress top etc)

Air filters

Wadding to be fed to a needle punching line to make Carpet support base.

Isolation articles protecting from sound and or temperature.