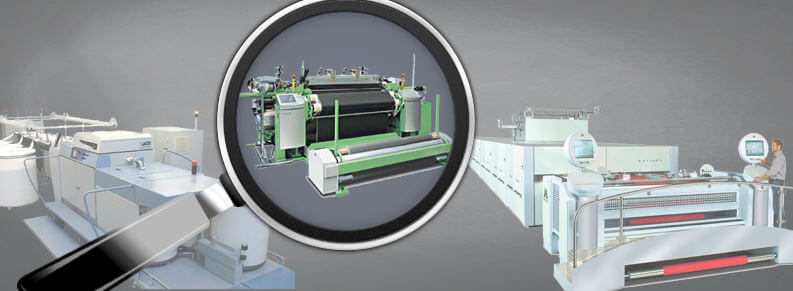

Complete open end spinning factory .

We are selling a small open-end Rieter spinning mill for recycled cotton. Please contact us to request our open end spinning plant price.

References

CCC/003

| Years | 2023 |

| Brand | . |

| Types | complete cotton open end spinning factory |

| Quantity | 1 |

| Location | Europe |

| New OPEN END SPINNING facility for Regenerated cotton fibers | |

Please log in to receive a personalized quotation.

COMPLETE RIETER OPEN END SPINING PLANT FOR REGENERATED COTTON

1 UNIfloc A 12

Connection to UNIcontrol and prepared for data

collection; Take-off unit 2300 mm.

1 Condenser A 22

1 UNImix B 72

With opening module;

Connection to UNIcontrol and prepared for data

collection.

1 Condenser A 21

+ Various accessories for blowroom machines

2 RIETER Cards type C 77

for up to 120 kg/h sliver production;

Card clothing for Regenerate;

Licker-in unit, with one roller and sawtooth clothing;

Can diameter at delivery side 1000 mm;

Can height 1200 mm to 1220 mm (48”).

+ Accessories for Cards.

1 Pneumatic fibre conveyance system

+ Various accessories

1 UNIcontrol

1 RIETER Drawframe RSB-D 50

Can diameter at feed side up to 1000 mm;

Power creel for a doubling of 6-fold, 2-rows up to

1000 mm cans;

Can diameter at delivery : 450 mm;

Can height at delivery : 1070 mm +/- 5 mm;

+ Various accessories for drawframes.

1 RIETER Open End rotor spinning machine type R 37 with 500 rotors

Machine

equipped with ASI system (Automated Spinning-In) for

fast automated startup after power failure

Spinning positions with electronic device for piecing

process by AMIspin-Pro system including single drive

for yarn delivery;

Winding prepared for 1°51' conical bobbins;

Rotor drive 2 x 22 kW;

Opening roller drive with frequency converter 2 x 18.5;

kW; Travelling cleaner;

Spinning units equipped with waxing devices;

Q10 yarn clearer;

Rotors, diameter 33 mm, type S533/U-D, diamond

coated, and nickel plated for rotor speeds up to 95'000

rpm;

Insert 7S5 for rotors 33 - 36 mm;

Opening units equipped with standard trash channel A

suitable for trashy and clean material;

Opening roller type S61-DN-64 v2, double-diamond coated

and nickel-plated wiring;

Draw-off nozzles, type: S-R7 RS.

+ Accessories for Rotor Spinning Machines

This spinning plant is from 2023 and runned only for a trial